ABS material is often used in the production of building block toys and figure production.

ABS Figures are collectible models made from Acrylonitrile Butadiene Styrene (ABS), a type of plastic known for its strength and durability. Here are some key points about ABS Figures:

Material: ABS is a copolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. This combination makes ABS stronger and more resilient than pure polystyrene.

Usage: ABS is often used for parts of figures that require more structural integrity, such as the legs or base. It is sometimes combined with PVC to create figures that are both detailed and sturdy.

Properties: ABS plastic is known for its shiny surface and ability to withstand low temperatures. However, it can be damaged by prolonged exposure to sunlight.

Applications: Due to its durability, ABS is commonly used in various applications, including toys, automotive parts, and household appliances.

ABS Figures are popular among collectors for their robustness and the high level of detail they can achieve.

The frequency of ABS used in the toy industry will be relatively low. Generally used to make base, sharp and transparent products.

Due to the characteristics of ABS, all products will have a clamping line. ABS products are usually used in combination with PVC.

Custom ABS Toy Production Guidelines

Minimum Order Quantity (MOQ) for ABS Toys:

For ABS toys, the minimum order quantity is 5,000 units.

We operate 3 ABS production lines, enabling us to manage large-scale orders efficiently.

Production Timeline for ABS Toys

How long ?

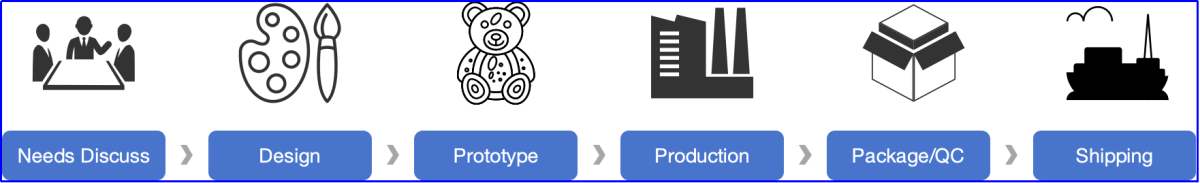

The complete production process, including prototyping, mold creation, mass production, packaging, and quality inspection, spans approximately 90-120 days.

The initial phase, which involves confirming prototypes and samples, typically takes around 2 weeks.

For urgent projects, expedited services are available for an additional fee.

Customization Costs for ABS Toys

As these are custom products, costs are calculated based on the specific design requirements.

Factors influencing the cost include:

*Product design

*Product size

*Quantity

*Number of colored parts

*Movable parts

*Accessories

*Packaging

The costs are divided into three main categories:

Since there are many links involved, you can inquire with us.

Reviews

There are no reviews yet.